Enovate Looks to (and Through) the SX10 to Keep its Team Productive

Joe Priestner, vice president of geomatics & technology at Enovate Engineering LLC, knows that all too well. Having worked in the survey and civil engineering industries for the past 30 years has taught him a thing or two about managing personnel, equipment and data, both in the field and from the office.

Enovate Engineering is a WBE engineering firm with offices in Charlotte, NC and Cranford, NJ that specializes in construction management services and has a research and technology division to address solutions that don't currently exist for problems the team has seen in the field and experienced firsthand. Enovate also provides on-site field services such as surveying and monitoring for both traditional and technologically advanced elements of projects.

From the beginning of his career, Joe has been a proponent of using the best technology for the job, particularly in surveying. In 2018, Enovate purchased a Trimble SX10 from Duncan-Parnell, Inc. as part of an effort to outfit a new survey vehicle. "We wanted a Trimble instrument; my past experience has shown Trimble equipment to be reliable - with less downtime. When we saw the SX10 come out, for just a few extra dollars, we could be carrying both a robotic total station and a laser scanner into the field with us and have it on every job. That was very attractive."

As part of his survey management, Joe has always strived to have remote access to data collectors in the field. In years past, crews would come into the office prior to going out on a job and would bring the data back to the office at the end of the day for download. With technology what it is today, crews are on the road more with less office time, so Enovate downloads and uploads files remotely to maximize their efficiency.

Recently, Joe was working from Enovate's Charlotte, NC office trying to support a crew working in the field at a jobsite in another city. The crew was staking out a building, and they were having issues. "I got on the SX10 and realized that I could see through the instrument. I could basically drive survey and act as the crew chief remotely. I could see what they were looking at, I could see what points they were measuring, that type of thing. I quickly diagnosed what was going on, so it was a neat realization that - wait a minute, all I need is somebody to set up the instrument in the field, and I can run it from anywhere." With the SX10, Joe could see that his crew chief was actually walking to the wrong place on the jobsite. He was able to quickly correct the layout issue and get the crew running again.

Previously, an issue like this would have potentially not shown up until the crew got back into the office and data was downloaded and reviewed - a lot of time and effort spent on something as simple as a misunderstood point location. For Joe, the ability to capture a laser scan while you're out measuring a few points and be able to combine the data relatively quickly is huge. There's no registration process. "As you're surveying, the instrument knows where it is. By eliminating the process of registration and going through a separate process of locating scan targets, it's more efficient to capture scan data. It's more cost effective, easier to support, easier to work with crews in the field - especially today with everything being remote. It makes a big difference in keeping the crews running efficiently."

The combined scanning and conventional data capture capabilities of the SX10 has changed survey processes at Enovate. They are collecting and using far more scan data than if they had to carry a separate scanner, because the scanner itself can be expensive, adding another $60,000 - $100,000 instrument that the crew would have to carry around and making it not very practical to have in every survey truck. They are making the SX10 their standard crew instrument, so they are using the laser scan data more. "It's almost like we capture anything that we might not have thought we needed when we were in the field. So the combination of imagery, scan data and the individual points - we have a richer dataset to work with. It's changed our workflows in that we now do a lot of combined scan data and conventional data, so that we don't have to return to the field to pick up stuff that was decided at a later time that we needed to show on our drawings."

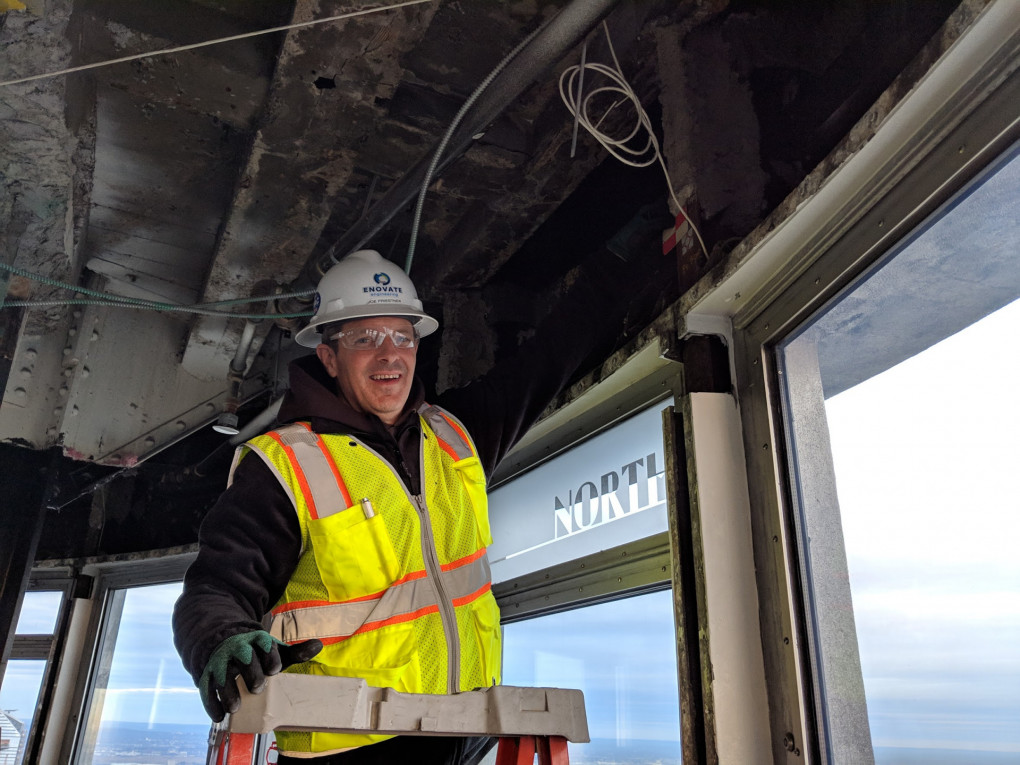

Recently Joe was working on a landmark building in New York City with the building moving in high winds - they were on the 102nd floor - and the instrument kept giving them an error, even with the compensators turned off. He called Mike Withers at Duncan-Parnell and Mike was able to give him the information he needed to correct the problem. They were back up and running in a matter of minutes.

Joe has had a long relationship with Duncan-Parnell having worked with them since the 1980's. "It's always been service that Duncan-Parnell is tops at. You can always call them, and they are very responsive. They know their equipment. It's all about service. When we're out in the field working and have an issue, we need immediate support to keep us productive, and Duncan-Parnell has always been there."

For Enovate, technology is a critical element in their workflows. Having trusted partners like Trimble and Duncan-Parnell to support that workflow plays a vital role in their efficiency.